Demonstrating the technical,

environmental, and economic feasibility of manufacturing high value-added

aircraft structural parts is the main objective of the ECO-CLIP project. To

achieve this goal, ECO-CLIP focuses its research on the replacement of

classical clip and bracket manufacturing processes with cost-effective and

easy-to-implement processes that enable near-net-shape manufacturing, such as

injection moulding and 3D printing.

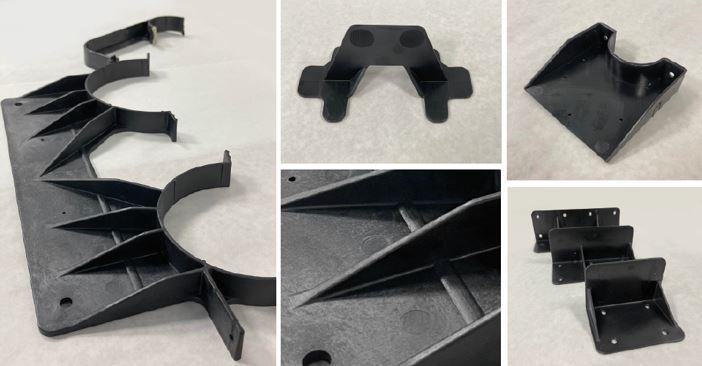

After months of research, the

ECO-CLIP project continues to achieve technical milestones. Recently, Aitiip

technology center, member of the ECO-CLIP’s consortium, has made progress in

the injection process, after concluding the previous stage of redesigning the

parts (frame clips and system brackets) to adapt them to this injection. It

should be remembered that the objective of ECO-CLIP is to replace those aeronautic

parts, now made of metal, with thermoplastic material.

In recent months, Aitiip has

focused its efforts on the manufacture of modular molds. Thanks to these molds,

it is possible to reduce the necessary investment to produce different

demonstrators in injection molding, as it is possible to manufacture different

pieces with only a small structural modification of the mold.

Once the design of the part and

the mold had been fulfilled, Aitiip team began the injection phase. In this

process, Aitiip has worked with the material developed by ECO-CLIP coordinator,

AIMEN Technology Center, based on 40% CF / recycled PAEK, obtained from

industrial waste and factory scraps from other processes. The manufactured

parts are currently under evaluation by GKN FOKKER and will be applied in the

STUNNING Multi-Functional Fuselage Demonstrator.

In the other side, AIMEN has also manufactured one of the bracket

geometries to validate the emerging FGF (Fused Granulated Fabrication) additive

manufacturing technology. This manufacturing system provides a fast and

cost-effective solution for small production runs or prototypes.

The fused granulated fabrication technique has been able the use the same

material as the one involved in injection molding. In contraposition to the

typically used FFF, which implies the development of high carbon fiber load

filament that usually represents a huge problem, this technique used pellet

extrusion to create layer-by-layer geometries, avoiding the decrease of carbon

fiber for 3D printing and continuing with high recycled material ratio.

For this aim, a destock printer has been modified within the project

framework to fulfill the necessities of this kind of high-performance materials

process by direct extrusion fabrication.

In addition, ECO-CLIP is

developing at AIMEN facilities an ultrasonic welding procedure for the newly

developed material to join the clips to the aircraft structure, thus avoiding

the need for mechanical joints, and allowing the reduction of both, costs, and

environmental impact.